There is a limit to what we can do on our own to solve social issues. We will create new value by working with companies, governments, universities, and research institutes across different industries and fields with a diverse range of knowledge.

Reducing Livestock GHG Emissions

The NH Foods Group has consistently been engaged in the production, rearing, and sale of pigs and chickens in Japan and cattle in Australia, and is aware that reducing greenhouse gas emissions (GHG) such as methane from livestock production is a major challenge.

Because methane has a greenhouse effect 25 times greater than CO2, we are currently conducting joint research with universities and producers’ groups in two directions: reducing methane generation and recovering and using the methane that is emitted.

| Hokkaido University | Develop Methods to Control Methane Generation in Bovine Rumen |

| Osaka University | Research porous organic salts with specific adsorption capacity for methane |

| University of Tokushima | Research on pig greenhouse gas emissions |

Japan’s First Chicken Manure Power Generation Business

In Miyazaki Prefecture, the Group is engaged in business activities in all processes, ranging from production to treatment, processing, manufacturing, and sales.

As part of these activities, our Miyazaki Production Division, which is in charge of the production, treatment, and processing of chicken, ships approximately 83,000 chickens per day raised at contracted production farms. In order to appropriately treat the excrement generated as these chickens are raised, Nippon White Farm Co., Ltd. established Miyazaki Biomass Recycle Co., Ltd. as Japan’s first chicken manure power generation business in May 2003 through joint investment by parties including poultry farmers, local agricultural cooperatives and other businesses* in Miyazaki Prefecture. The company has the capacity to generate

76,662 MWh annually, which is enough power to supply roughly 20,000 residential households. It has sealed facilities as a measure against odor influence on the surrounding environment.

Note: Agricultural cooperatives: Koyu Chicken Produce of Miyazaki Cooperative, Miyazaki Environmental Conservation and Agriculture Cooperative, Miyazaki Biomass Utilization Agricultural Cooperative

Companies: Koyushokucho Co.,Ltd., Nippon White Farm Co., Ltd., Wellfam Foods Corporation,Yamashita Shoji Limited, Kyuden Mirai Energy Inc.

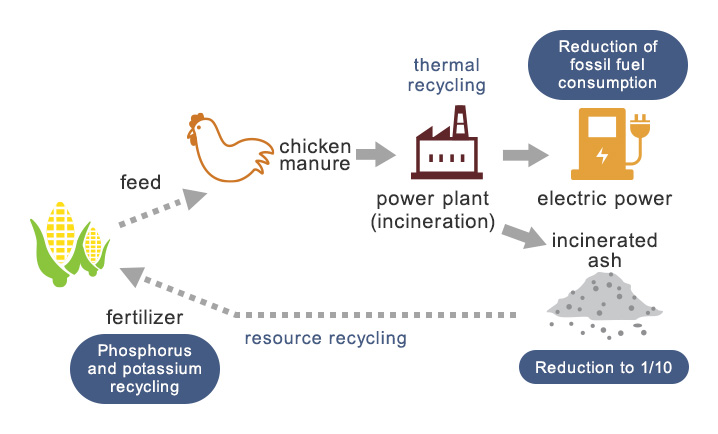

■Conceptual Image of a Cyclical Ecosystem (Biomass Power Generation)

The Flow from Chicken Manure to Electric Power

Approximately 43,000 tons of poultry manure is generated each year from production farms contracted by the Miyazaki Production Division of Nippon White Farm Co., Ltd. Approximately 90% of it is delivered to Miyazaki Biomass Recycle Co., Ltd., to generate electricity from the energy produced from incineration.

■Incineration Capacity of Miyazaki Biomass Recycle Co., Ltd.

Amount of incinerated poultry manure: 132,000 tons/year

Amount of power generated: 76,662 MWh/year*

Note: Compared with coal thermal-power generation, this is equivalent to a CO2 reduction of 66,000 tons and annual power consumption for approximately 20,000 general households.

The Flow from Incineration Ash to Fertilizer

The ash remaining after chicken manure is incinerated is purchased by the Miyazaki Environmental Preservation Agricultural Cooperative, sold to NH Foods Ltd., fertilizer producers, and others, and distributed on the market.

The incineration ash is sold as organically-derived fertilizer that contains phosphorous and potassium and contributes to improving soils.

Chicken manure is continuously and effectively used as a resource, leading to reductions in the environment impact and cyclical use in cooperation with other companies.