The NH Foods Group Quality Assurance System

~ To Deliver Safe Products to Our Customers ~

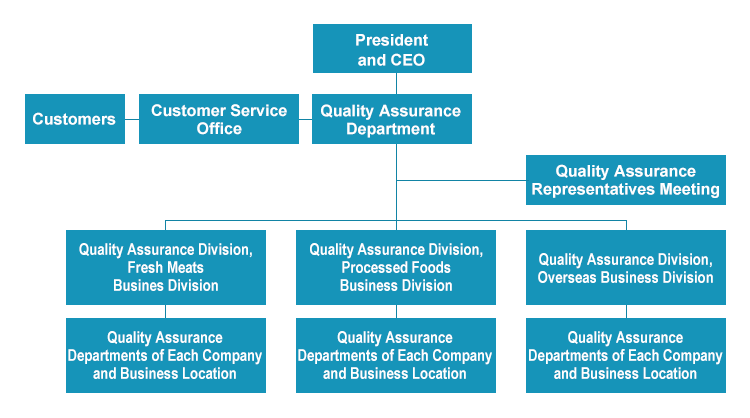

1. Quality Governance Organizational Structure

The NH Foods Group promotes quality assurance activities across the entire group, including the planning of group-wide quality assurance strategies and the formulation and sharing of various policies.

By sharing knowledge and know-how on quality risk information and measures, we aim not only to prevent quality incidents but also to establish a system that can respond swiftly in the event of an accident.

Response to Quality-Related Incidents

In case of an inquiry or feedback from customers, our customer service center and sales department will receive it, and the information will be shared daily among departments such as factory, sales, development, quality assurance, and the management team to ensure swift actions and improvements. In case of an incident, we swiftly report it to the President and establish a crisis management headquarters. Prioritizing the prevention of health hazards, we will recall the affected products.

2. The NH Foods Group Quality Assurance System

The NH Foods Group considers delivering safe products to be a social responsibility.

Therefore, we organically integrate the three functions of safety review, quality audit, and safety inspection while fostering the personnel involved in these areas.

We are committed to a system that ensures safety across the entire group.

Quality Policies

The NH Foods Group leverages its proprietary quality assurance system to realize transparency in food production.

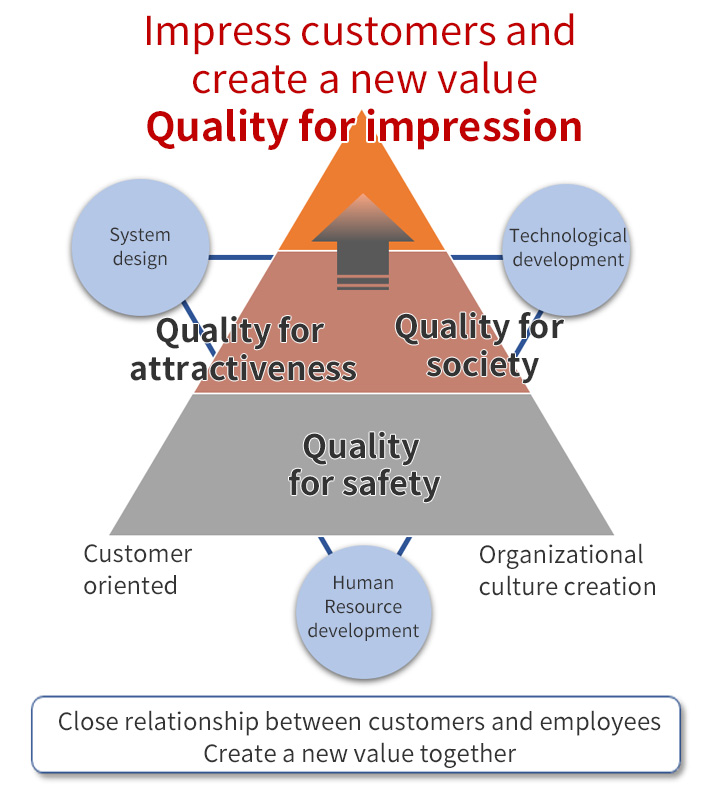

NH Foods group quality policy

The NH Foods group has identified 3 types of quality required for products and services Quality for safety, Quality for attraction, and Quality for society. Training our personnel and developing technologies and systems will be advocated to achieve this. We will contribute to the joy of eating and healthier and better lives through safe and high-quality products and services for our customers.

- We value the communication with our customers and provide products and services that meet their expectations.

- We will challenge ourselves to impress our customers and create new value through the pursuit of high quality and good eating and free thinking.

- We will comply with laws and regulations, improve our food safety initiatives from the farm to the table, and provide our customers with the appropriate information.

- We value the bounty of life, strive to improve the sustainability of our products and services, provide a stable supply of food, and work towards resolving social issues.

- We consider quality as the most significant value of our group, and we continuously engage all employees in the creation of a culture centered around people, technologies, and systems to strive for safety and superior quality.

Quality for safety

To make our customers feel secure when they choose our products, we must ensure the safety not only of our products, but also related information and services. In addition, we will challenge ourselves to create a quality that impresses our clients, as well as generating new value that contributes to a better life for our customers.

Quality for attractiveness

It is important that the products and services that our customers choose are attractive. We will continue to develop and improve our products and services through communication with our customers. In addition, we will challenge ourselves to create a quality that impresses our clients, as well as generating a new value that contributes to a better life for our customers.

Quality for society

The products and services that our customers acquire must consider current and future social issues, such as those related to the environment, health, food diversity, etc. To fulfill our responsibility to provide a stable food supply in the future, we will improve the quality of our products and services to meet the demands of society and contribute to solve social problems.

Safety Assessment

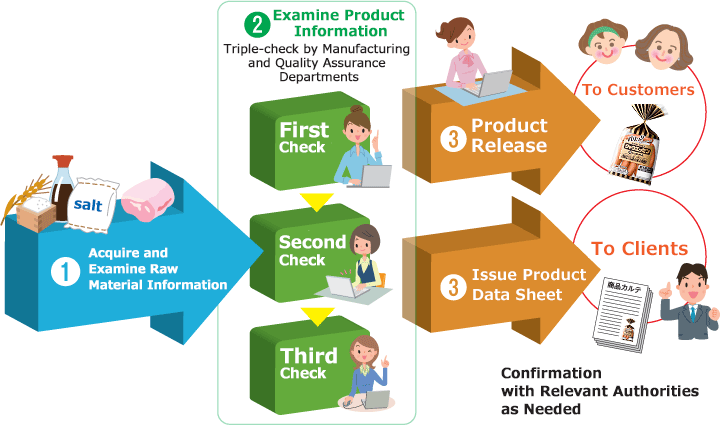

What is a Safety Assessment?

Before launching a product, we review and confirm the safety of raw materials and check for compliance with labeling and standards regulations. Additionally, we communicate important information to our customers through product labeling and product data sheets.

We conduct assessments from these perspectives.

Review Flow

- Acquisition of Raw Material Information Product information is built up from raw material information. Acquiring raw material information is the first and most crucial step.

- Examination of Product Information Combining the raw material information that has been confirmed for safety, we establish the quality standards for the product. Only products that have been approved at all stages of safety verification are commercialized.

- Product Launch and Issuance of Product Data Sheets We provide accurate product information to our customers.

Review Contents

We rigorously review from various perspectives to ensure safety.

* FT-CCP: Fresh & Tasty Critical Control Point

An original initiative by the NH Foods Group, meaning key management items for "freshness and tastiness."

Comprehensive Product Information Management System

We have established a system to manage accurate raw material information and ensure compliance with regulatory requirements for accurate product information.

Quality Audit

What is NH Foods Group Quality Audit?

To deliver safe and reliable quality products to our customers, NH Foods group's quality assurance personnel work together to verify items related to food safety and quality at production areas, manufacturing plants, and sales bases both domestically and internationally.

NH Foods group primarily conducts the following audits:

- Audits based on NH Foods group's common quality policies and food safety standards. (Conducted by NH Foods Ltd. Quality Assurance Department at least once a year)

- Internal audits related to food safety at each site. (At least once a year)

- Mutual audits on food safety between different sites. (Irregular)

- Second-party audits by business partners. (Irregular)

- Third-party audits by certification bodies related to food safety. (Once a year)

Additionally, we ensure that our domestic and international contract manufacturers understand the NH Foods group's quality philosophy and request improvements as needed.

Philosophy of NH Foods Group Quality Audit

We aim to deliver safe products to our customers by continuously improving the manufacturing environment.

We continuously improve the manufacturing environment by conducting audits and repeatedly verifying and improving the results.

Establishing quality audit items based on NH Foods Group Quality Assurance Regulations

Items Checked During Quality Audits

- Company quality rules

- Items reflecting current affairs

- Latest domestic and international laws and information

- Customer feedback and complaints

- Items complying with international standards and modern requirements

Review of contents based on risk analysis and evaluation

- Risks Occurring in the Food Industry (Raw material origins, food fraud, foreign matter contamination, etc.)

- Trends in the industry, academic societies, and domestic and international government actions

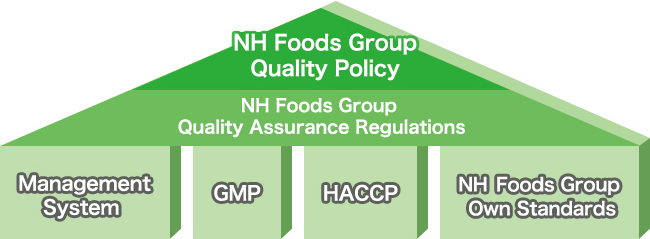

What are NH Foods Group Quality Assurance Regulations?

These regulations set out the basic requirements to ensure the safety and quality of products sold and provided by the NH Foods Group.

The requirements include three pillars: HACCP, FSM (Food Safety Management) such as "Management Responsibilities" and "Design and Development Reviews," and GMP (Good Manufacturing Practices) like "Production Process Control," in addition to NH Foods Group's unique standards.

Human Resource Development

Supporting our quality are the "people". At the NH Foods Group, we are committed to developing human resources to ensure reliable quality.

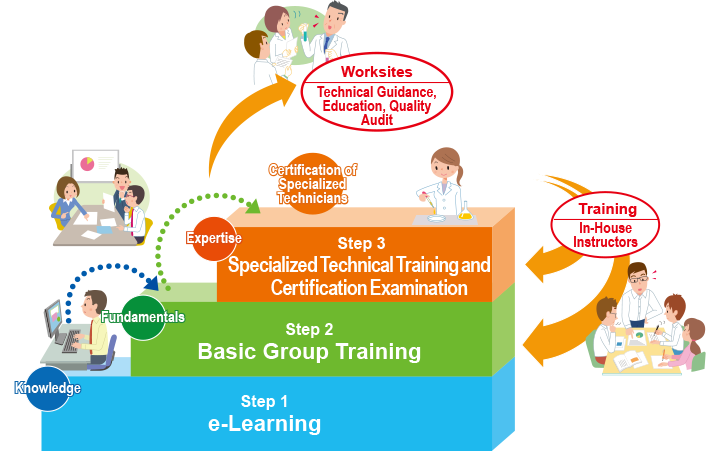

Human Resource Development for Enhancing Quality Assurance Technology at NH Foods Group

The NH Foods Group has established a systematic approach to human resource development aimed at improving quality assurance technology. We are progressing the training of specialists equipped with expert knowledge and technical skills, starting from a foundational knowledge base. We have implemented e-learning so that many individuals can learn at their own pace. In group training sessions, participants confirm their basic knowledge while enhancing their technical skills through practical exercises, striving for further level-up and improvement.

Flow and Content of NH Foods Group Human Resource Development

Step 1: e-Learning

Through e-learning, employees can use PC to repeatedly study knowledge related to quality assurance at their own pace. The e-learning content has been uniquely developed by NH Foods Group and is provided uniformly to all group companies, including those overseas. This ensures that everyone involved in operations has the opportunity to learn.

◇Types of e-Learning

Fundamentals of Quality Assurance

QC Methods

Foreign Object Inspection Equipment

Food Laws and Labeling

Cleaning Techniques

Food Microorganisms

Pest Control

Food Allergies

English Version: Fundamentals of Quality Assurance

Step 2: Basic Group Training

We have developed a unique curriculum that includes both classroom lectures and practical training. Through these, participants acquire technical skills and knowledge necessary for their roles. Only those who demonstrate satisfactory outcomes in the post-training assignments are given completion certification.

Step 3: Specialized Technical Training and Certification Examination

Selected personnel from all group companies undergo advanced technical training to develop into top-notch engineers. Individuals who pass our unique examination system are certified as specialized technicians. These certifications are assessed objectively by third parties or individuals holding equivalent qualifications. Certified specialists also act as instructors for site technical guidance, education, basic, and specialized training.

◆Main Education and Training on Basic Knowledge for All Employees

- e-Learning for Understanding the "NH Foods Group Quality Policy"

- e-Learning for Understanding the "NH Foods Group Quality Assurance Regulations"

Education, Training, and Achievements Related to Quality

(Unit: People)

| Educational Content | Main target participants | Frequency | 2021 | 2022 | 2023 |

|---|---|---|---|---|---|

| Quality e-Learning Participants | Everyone | Twice a year | 3,754 | 2,468 | 2,047 |

| Basic Technical Training Participants | Manufacturing, Quality Assurance | Twice a year | 70 | 64 | 107 |

| Applied Technical Training Participants | Manufacturing, Quality Assurance | Once a year | - | - | 18 |

| Specialized Technical Certification Exam Successful candidates | Manufacturing, Quality Assurance | Once a year | 4 | 2 | 0 |

| Intermediate Level Food Labeling Certification Successful candidates | Quality Assurance, Product Development, Sales | Twice a year | 65 | 57 | 37 |

| Advanced Level Food Labeling Certification Successful candidates | Quality Assurance, Product Development, Sales | Once a year | 11 | 11 | 1 |

| Prize and Labeling Law Certification Successful candidates | Quality Assurance, Product Development | Once a year | 2 | 3 | 8 |

| External Management Test for Inspection Accuracy | Inspection and Analysis, Quality Assurance | Once a year | 54 | 49 | 46 |

Evaluation by External Organizations

Obtaining objective evaluations from External organizations allows us to continuously improve our quality assurance standards.

We promote the acquisition of External certifications for safety and security.

We are committed to not only evaluating our quality assurance system from our own perspective but also obtaining objective evaluations from External perspectives to further enhance our standards. The NH Foods Group has acquired External certifications related to quality assurance such as FSSC22000, SQF, ISO9001, and HACCP, and we continuously strive to improve our quality assurance levels.

Status of External Certification Acquisition by NH Foods Group

Number of Manufacturing Sites: 83

HACCP-Implemented Sites: 100% (83 sites)

GFSI Standard Certified Sites: 73.5% (61 sites)

- *As of March 2024

- *Some sites have obtained multiple certifications.

HACCP

Hazard Analysis and Critical Control Points: A management system that oversees the entire production process to prevent health hazards in food production, not just the final product.

ISO9001

An international standard for quality management systems established by the International Organization for Standardization (ISO) in 1987.

ISO22000

An international standard for food safety management systems aimed at producing, distributing, and selling safe food, based on HACCP methods and ISO9001 requirements.

FSSC22000

One of the food safety management systems, combining ISO22000 (food safety management system) and ISO/TS22002-1 (prerequisite programs on food safety).

SQF

An international management system for identifying and verifying food safety and quality management methods.

BRC

A food safety standard established by the British Retail Consortium, which also includes requirements for quality and regulatory compliance. It is one of the most widespread standards approved by GFSI, especially in Europe and the USA.

ISO17025

An international standard specifying the general requirements for the competence of testing and calibration laboratories.

JFS Standards (JFS-A/JFS-B/JFS-C)

A food safety standard developed in Japan by the Japan Food Safety Management Association (JFSM). It is divided into three levels (A, B, and C), with the C standard being an internationally recognized standard approved by GFSI.

| Company Name | Main Products | Number of Sites | Certifications and Number of Sites |

|---|---|---|---|

| NH Foods Ltd. | Processed Foods, (Research and Development, Inspection and Aanlysis) | 1,(2) | FSSC22000: 1 site,(ISO17025:2sites) |

| Nipponham Factory Ltd. | Ham, Sausage | 5 | FSSC22000: 5 sites, HACCP: 1 site |

| Nipponham Hokkaido Factory Ltd. | Ham, Sausage, Dry-Cured Ham | 3 | FSSC22000: 2 sites,JFS-B: 1site |

| Nipponham Northeast Ltd. | Ham, Sausage | 1 | FSSC22000: 1 site |

| Kyodo Foods Co.,Ltd. | Ham, Sausage | 2 | FSSC22000: 2 sites |

| Kamakura Ham Tomioka Co., Ltd. | Ham, Sausage | 1 | FSSC22000: 1 site |

| Nipponham Processed Foods Ltd. | Processed Foods | 3 | FSSC22000: 3 sites |

| Nipponham Delicatessen Ltd. | Processed Foods | 3 | FSSC22000: 3 sites, ISO22000: 3 sites |

| Nipponham SouthWest Ltd. | Meat Processing, Extracts, Ham, Sausage, Processed Foods,(Inspection and Aanlysis) | 6,(1) | SQF: 2 sites, FSSC22000: 2 sites, ISO9001: 1 site, JFS-B: 1 site, (ISO17025:1site) |

| Nippon Pure Food,Inc. | Extracts, Processed Foods | 7 | FSSC22000: 3 sites, ISO22000: 7 sites, ISO9001: 1 site |

| Nippon Luna, INC. | Dairy Products | 2 | FSSC22000: 2 sites |

| Hoko Co., Ltd. | Cheese, Dairy Products, Canned/Bottled Foods, Freeze-Dried Foods, Processed Foods | 4 | FSSC22000: 2 sites, ISO22000: 2 sites, JFS-C: 1 site |

| Premium Kitchen Co. Ltd. | Cooked Foods, Frozen Foods | 2 | JFS-B: 2 sites |

| Nippon Clean Farm Ltd. | Pig Farming | 4 | SQF: 4 sites |

| Nippon Food Packer Inc. | Livestock Processing, Oils, Feeds | 6 | SQF: 6 sites |

| Nippon White Farm co.,Ltd. | Poultry Farming, Chicken Processing | 10 | SQF: 10 sites |

| Higashi Nippon Food, Inc. | Meat Sales, Processing | 1 | JFS-B: 1 site |

| Kanto Nippon Food, Inc. | Meat Sales, Processing | 2 | JFS-B: 2 sites |

| Naka Nippon Food, Inc. | Meat Sales, Processing | 3 | JFS-B: 2 sites |

| NHJF Corporation | Meat Sales, Processing | 1 | HACCP: 1 site |

| Usune Co.,Ltd. | Meat Processing | 1 | SQF: 1site |

| Oakey Beef Exports Pty. Ltd. | Beef Processing | 1 | HACCP: 1 site, BRC: 1 site |

| Wingham Beef Exports Pty. Ltd. | Beef Processing | 1 | HACCP: 1 site, BRC: 1 site |

| Thomas Borthwick & Sons Pty. Ltd. | Beef Processing | 1 | HACCP: 1 site, BRC: 1 site |

| Redondo's, LLC | Ham, Sausage | 1 | HACCP: 1 site |

| Day-Lee Foods, Inc. | Meat, Seafood, Processed Meat Products | 1 | HACCP: 1 site, SQF: 1 site |

| Ege-Tav Ege Tarım Hayvancılık Yatırım Ticaret ve Sanayi Anonim Şirketi | Poultry Farming, Processing, Sales | 1 | FSSC22000: 1 site, ISO22000: 1 site, HACCP: 1 site, BRC: 1 site, ISO9001: 1 site |

| Shandong Rilong Foodstuffs Co., Ltd. | Processed Foods, Ham, Sausage, Freeze-Dried Foods | 1 | FSSC22000: 1 site |

| Pure Food Asia, Inc. | Extracts, Seasonings, Processed Foods | 1 | FSSC22000: 1 site, ISO22000: 1 site, HACCP: 1 site |

| Thai Nippon Foods Co., Ltd. | Processed Foods, (Inspection and Analysis) | 2,(1) | FSSC22000: 2 sites, ISO22000: 2 sites, HACCP: 2 sites, BRC: 1 site, ISO9001: 2 sites, (ISO17025:1site) |

| NH Foods Vietnam Joint Stock Company | Ham, Sausage, Processed Foods | 2 | FSSC22000: 1 site, HACCP: 1 site |