The NH Foods Group is working to reduce CO2 emissions from fossil fuels in 2030 by more than 46% compared with FY2013 levels in Japan and by more than 24% compared with FY2021 levels overseas.

To achieve this goal, we strive to reduce CO2 emissions associated with its business activities, installing solar panels, converting fuel from heavy fuel oil to gas, using biomass resources such as animal and plant waste oil and livestock manure, and installing energy-efficient equipment.

Installation of Solar Power Generation

The Group is promoting the installation of solar power generation on the grounds of our business sites and on the roofs.

As of March 2025, 40 solar power generation installations.

In order to achieve our target for 2030, the Group will promote the introduction of renewable energy, including off-site models that use electricity generated at installations located outside of our business sites.

Solar power generation results (April 2024 - March 31, 2025)

| Number of power generation sites *1 | Annual power generation(MWh/year) | Percentage of annual electricity consumption in Japan (%) |

CO2 reduction (t-CO2/year) *2 |

|---|---|---|---|

| 40 | 11.215 | 2.0 | 4,443 |

Note1: 1 As of March 31, 2025

Note2: Calculated based on the CO2 emission factors of the power company on which each business site which solar power installed purchases.

Fuel-Related Measures

Fuel Conversion from Heavy Fuel Oil to LNG and LPG

Four plants in the Group have switched their boiler fuels from heavy fuel oil to liquefied natural gas (LNG) or liquefied petroleum gas (LPG), which emit less CO2. Fuel conversion is also planned for two additional plants.The five plants that have been established in recent years do not use heavy fuel oil, instead using electricity and gas as energy sources to reduce CO2 emissions.

Use of Animal and Vegetable Oil as Boiler Fuel

Boilers are mainly fueled by heavy fuel oil and gas, but six plants in our Group have introduced waste oil boilers that use animal and vegetable oil from the food production process to reduce CO2 emissions.

We are considering installing waste oil boilers at multiple other plants in addition to the existing plants.

Use of Manure as Fuel

Some of the chicken manure from the farms is burned as a fuel in boilers and the hot water produced is used for heating and cleaning the poultry houses.

Learn more Use of Manure as Fuel

Biogas Plant

Oakey Beef Exports Pty. Ltd., which processes cattle in Australia, installed a biogas plant in April 2015 to extract methane gas generated from factory wastewater and use it as a source of energy.

Through this actions, we are working to reduce the use of natural gas and CO2 emissions.

Energy-Saving Initiatives

Refrigerator Upgrades

Nipponham Processed Foods Ltd.’s Kanto Plant, which is engaged in the manufacture of processed foods, is reducing the amount of electricity it uses by replacing its refrigerators.

They are also working to improve the efficiency of electricity use by installing energy-saving equipment and reviewing operating hours.

Upgrading to High-Efficiency Boilers

At Nippon Pure Food, Inc.’s Nishinomiya Plant, which engages in the manufacture of processed meat, boilers have been replaced with high-efficiency boilers, and the tank piping has been modified to take advantage of previously unused heat in order to raise the boilers’ water supply temperature, reducing fuel consumption.

Installation of High-Efficiency Boilers

Nippon White Farm Co., Ltd., which handles production, treatment, and processing of chicken, uses boilers to heat its poultry houses.

Measures are being considered to reduce CO2 emissions by introducing high-efficiency boilers and gas boilers on a trial basis.

Use of Cogeneration Systems

Five plants in our Group use cogeneration systems.

A cogeneration system is equipment that generates electricity using gas, and then uses the heat generated during power generation to create steam and hot water, thereby using energy efficiently.

Installation of Waste Heat Recovery Compressors

We installed waste heat recovery compressors at several plants in the Group.

Until now, the heat generated when compressing air was discarded, but by using this heat to create hot water and feed the boiler, the amount of fuel used for the boiler will be reduced.

Installation of Turbo Blowers for Wastewater Treatment

Turbo blowers have been installed in wastewater treatment facilities at several of the Group’s plants, which are more efficient and save energy compared to the previous blowers.

Installation of Heat Pumps

Heat pumps have been installed to heat some of the poultry houses at Nippon White Farm Co., Ltd.’s Shiretoko Office.

Heat pumps are a technology that collects and uses heat in the air, requiring little energy.

We have installed a single heat pump to verify whether it will reduce energy use and CO2 emissions throughout the year compared to a conventional hot water boiler.

Upgrading to LED Lighting

The NH Foods Group is aiming to gradually switch to LED lighting as the standard lighting in properties we own at Group business sites in Japan.

As of the end of March 2022, about 90% of our target lights have been switched.

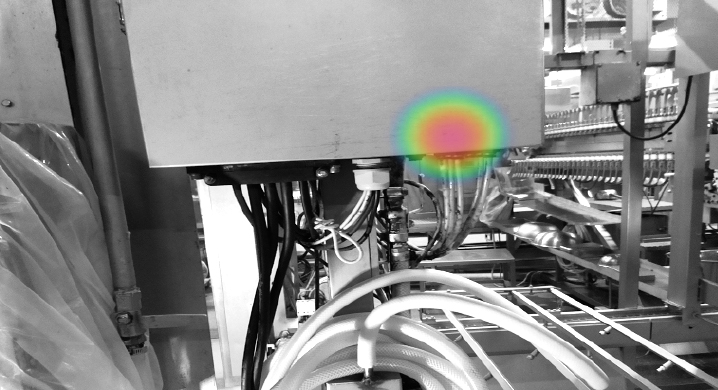

Identifying Air Leakage Locations

We are using air leak detectors, which use ultrasonic waves to show where compressed air is leaking, and are repairing air leaks discovered at our plants.

Eliminating air leaks leads to a reduction in the extra energy consumed to create compressed air.

Vehicle Fuel Initiatives

Introduction of Hybrid Trucks and Electric Vehicles

In February 2022, NHJF Corporation, which engages in the sale of fresh meat and other products to the restaurant industry, introduced hybrid trucks as part of its efforts to reduce CO2 emissions.

Additionally, NH Foods Marketing Ltd., which engages in the sale of ham, sausages, and other processed foods, has introduced electric vehicles for the cars it uses for sales activities. Electric vehicles have also been introduced at Nippon White Farm Co., Ltd.’s business site in Miyazaki.

Moving forward, we will examine their effect on reducing CO2 emissions and consider further introduction.

More Efficient Shipping

Nippon Dairy Net Co., Ltd. which handles the distribution of ham, sausages, and other processed foods, is reviewing loading efficiency and transport routes and is working to raise transport efficiency among the Group manufacturing plants and centers.

Other Initiatives

Introduction of the ICP

The Group employs Internal Carbon Pricing (ICP) in its investment decision-making process as a measure to reduce CO2 emissions.

- Internal carbon price: 5,500 yen/t-CO2

- Introduction targets: Capital investments involving CO2 emissions *1

- Utilization: Reduction of investment criteria

Note1: Investments meeting specific conditions stipulated in the internal rules