The sources of the Group’s business are the gifts of the earth and its expansive natural environment as well as the vast bounty of nature. Therefore, we believe in using this bounty with respect and leaving nothing to waste. However, it is inevitable that various unneeded things will be generated through business activities and production processes.

We work to reduce the generation of these unneeded things as much as possible by introducing new technologies that enable us to use them effectively. In this way, we ensure the effective use of limited resources.

Effective Use of Livestock Waste

The Group has created a Vertically Integrated System from raising and producing livestock to marketing, for cattle, pigs, and chickens.

Through this system, we provide safe and secure products to customers and are able to make full use without waste of the various resources generated during meat processing (such as bones and hides).

Bones are boiled to make ingredients for soup and condiments, and hides are used as a material for bags and other products. In addition, collagen is extracted for use as an ingredient in health foods.

Research and Development of Bio-Resources for Health

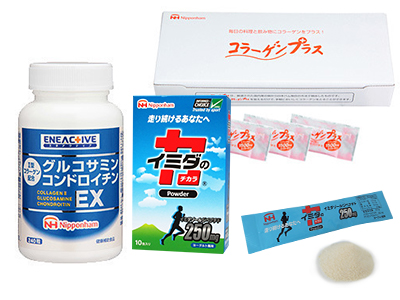

The NH Foods Ltd. Research &Development Center uses the Group’s abundant bio-resources to conduct research and development that is useful for healthy lifestyles.

We obtain collagen, placenta extract, chondroitin, and other functional materials from pig and chicken cartilage, pig placentas, and other organs, which in the past were not adequately utilized. We scientifically evaluate them for safety, effectiveness, and so on, and then commercialize them.