Due to their excellent hygienic, sealing, and other properties, plastics play an important role in protecting food quality, yet there are concerns about the issue of marine plastics and their other impacts on the global environment.

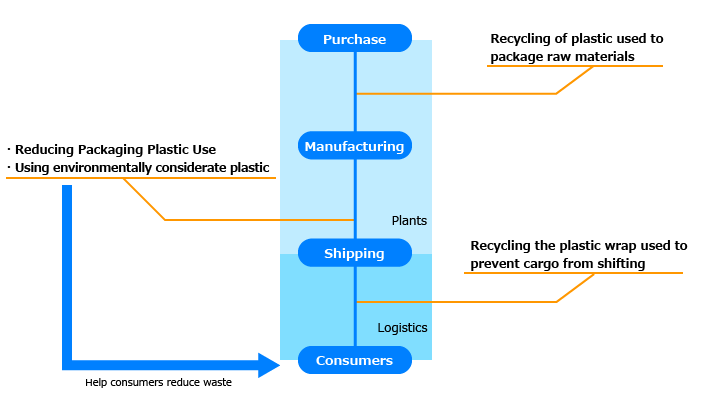

Since the NH Foods Group uses plastics at various stages, from purchasing raw materials to manufacturing and delivering products to customers, we have positioned plastics as a key issue, and are taking the following approaches under the premise that product safety is a top priority.

- Reduce the amount of plastic used in all areas

- Switch from using fossil-sourced plastics to using materials that consider the global environment

- Promote recycling of discarded plastic

Medium-to Long-Term Targets(to Fiscal 2030)

Materialities Progress Report FY2022 [138 KB / 4pages]

Case Study

Considerations Regarding the Material Recycling of Plastics

The Hyogo Plant of Nipponham Factory Ltd., which engages in the production of hams and sausages, is working to reduce waste by sorting, collecting, crushing, washing, and dehydrating its packaging materials for raw meat.

We are also examining the possibility of utilizing plastics separated from waste at our business locations for material recycling.

Reducing Packaging Plastic Use

Wieners

Packages replaced drawstring pouches with pillow packaging for the SCHAU ESSEN and other core wiener products.The new packaging has been named Eco-Pirotype packaging. Changes to the design have reduced the amount of material used by about 28%, which is expected to cut annual CO2 emissions by approximately 4,000 tons.

Note1: Comparison refers to SCHAU ESSEN 127g double pack with drawstring (comparison of film weight)

Note2: Value as of January 20, 2022, calculated using shipment quantities in fiscal 2020 (based on research by NH Foods Group)

SCAU ESEEN series

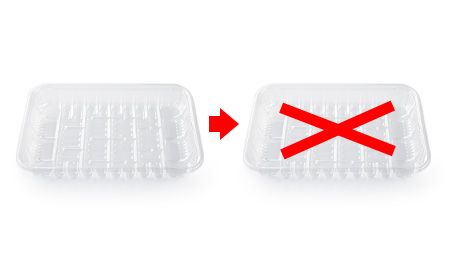

Chuka Meisai

For some of our products in the Chuka Meisai series, we have removed the tray that was previously placed under the product, reducing the amount of plastic in the packaging by 19.3%, which amounts to about 111 tons* over a six-month period. (Compared to previous packaging)

Note: Calculated based on sales data for four products (Subuta, Happosai, Chinjao Rosu, Hoikoro) from October 1, 2022, to March 31, 2023

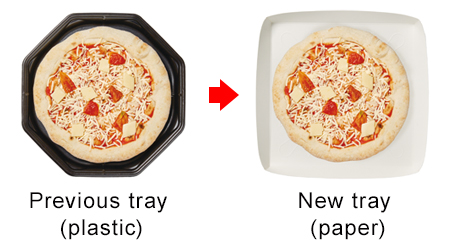

Kanade Specialty Margherita

Switching to paper trays and shrinking the exterior packaging has reduced plastic use by 37%*.

Note: Compared to the previous version of the same product

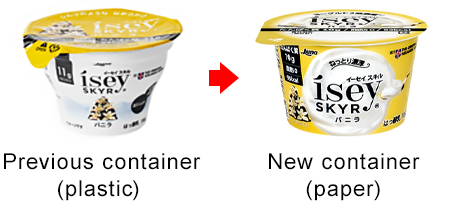

Nippon Luna Inc. Ísey SKYR series

We have switched the containers of Ísey SKYR, a series of Icelandic high-protein dairy products that we launched in Japan, from plastic to paper. Switching to paper containers has reduced plastic use by 94%*.

Note: Compared to the previous version of the same product

Using environmentally considerate plastic

Irodori Kitchen series

We are using recycled PET film as part of the packaging.

Entier series

We are using recycled PET film as part of the packaging.

Domestic chicken”Sakurahime chicken farm packs”

A plant-derived biomass film is used for packaging lids.

Domestic chicken “Sakurahime chicken farm packs” is vacuum-packed at the production site, meaning it can be displayed in stores without having to be re-packaged to be sold at volume retailers, etc.

Note: Information in each case study is current as of April 2024.

Recycling the plastic wrap used to prevent cargo from shifting

As the entity responsible for the distribution of our products, Nippon Daily Net Co., Ltd., is working to recycle the plastic wrap used to prevent cargo from shifting, which is currently discarded.

The company produces handbags that contain the collected film at a ratio of about 20%, which are then used at events organized by the Group, for example. The company is also examining whether this film can be converted into a raw material for reuse in plastic wrap.